RFID Tagging

This site is focused on applying RFID tags to TechOps components

– not baggage, cargo, passengers or anything else.

Delta is the aviation industry’s RFID poster child for doing it right and using RFID extensively. (Delta has no relation with this site)

Quickly figure out how to get this parts tagging accomplished with this guide. The guidance is correct – but is not exhaustively thorough as you would soon get lost in the technical weeds. It is meant to get your company started, but not answer every detailed question you will have – there are people to talk to for that. It distills 125 pages of ATA Spec2000 RFID standard, 150 pages of the ATA Common Support Data Dictionary, the GS1/EPC RFID standard, pertinent SAE standards and the FAA’s Aircraft Circulars on RFID.

The end result is that you will be able apply correctly formatted – Human Readable, Barcode and RFID data – to your parts to meet the aviation industries global requirements. Hundreds of major airlines, airframe manufacturers and component suppliers have been doing this for a decade. If you plan to be in the aviation business 5 years from now, we encourage you to join now with the rest of the industry!

WHAT IS NEEDED

Component RFID Tagging

Determine how your company (or just a product line) serializes the parts. Only two possible choices:

- Serial Number is unique within your CAGE Code (Preferred) (e.g., a single serial #100 across the entire company)

- Serial Number is unique within the Part Number which is unique within your company CAGE Code. (e.g., other parts can have a serial # 100 also)

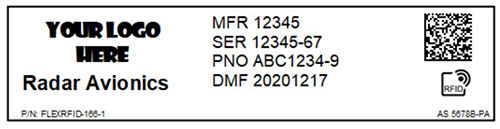

RFID tags require the part’s Birth Record data to be printed and barcoded on the tag and encoded in the chip. The Birth Record print, barcode and encoded data must be identical. Required data:

- Your company CAGE Code

- Serial Number (or SEQuence Number if using 2nd method in item A above)

- Part Number

- Date of Manufacture

Example of a complete RFID Tag:

Decide where that Birth Record data is coming from – ideally straight from your production system so it all remains digital and there will be no typos.

If the data cannot come direct from a production system and has to be printed out and typed back in, consider printing each piece of data in a barcode format so that can be read back into the RFID software using an inexpensive barcode scanner – no typos that way!

You must have 3rd party, ATA Spec2000 RFID software to encode the chip correctly. There are LOTS of subtle, technical requirements and the aviation-specific software is the only way to encode correctly.

You need an RFID printer to print and encode the tags. The print and encoded data has to be identical. The smallest, low volume printer will cost about $2700, a normal one will be $4700

You will probably also need an RFID reader to read the encoded data for a QA check. The reader also must run a Spec2000 RFID data application – a generic reader will only display garbage. Your software supplier can recommend one.

RFID Tags – these must meet FAA requirements for flammability and shake’n’bake tests.

- The standard is a 2 kilobit tag that has a large EPC Memory and User Memory to hold the Birth Record data. There are only a few suppliers of these FAA-certified tags

- The tags have SAE-required printing on the front, usually done by the RFID software.

- Tags must be appropriate for the part its being applied to. Simple, gummed RFID labels do not work on metal/conductive parts – you will need a metal mount label.

- The adhesive and label are supposed to last the life of the part.

Printing on the face of the label must include the Birth Record data, plus the RFID label’s part number and a reference that it meets the SAE AS 5678B-xx criteria.

RFID data encoded in the tag has other subtleties, such as which serialization schema are you encoding to and what the filter bit is for that type of part. See other pages for these details – or contact me for more info.

CONTACT US FOR MORE INFO OR ANY QUESTION

Send a Message

(There are dozens of details not explained here. The contact is free and I’ll only answer your question. I’m an engineer – not a salesman)

Understanding Spec2000

RFID Guidelines

Introduction